As Vietnam’s manufacturing sector accelerates and steps deeper into global competition, the pressure on enterprises has never been greater: reducing costs, boosting productivity, ensuring quality, and complying with international standards.

To meet these demands, manufacturers can no longer rely solely on ERP systems or fragmented manual reports. They need a “nervous system” that monitors, orchestrates, and analyzes production activities in real time.

Implementing MES not only gives enterprises visibility into factory operations — it turns operational data into a genuine competitive edge. Below are four key strategic benefits:

1. Enhancing Global Supply Chain Competitiveness

According to Aberdeen Group, manufacturers implementing MES can cut downtime by 15–20% and increase Overall Equipment Effectiveness (OEE) by 25–30%.

MES captures machine status, monitors each production stage, visualizes real-time progress, and issues immediate alerts when abnormalities occur.

2. Ensuring Quality and Full Traceability

MES enables quality control at every production stage: raw material intake, assembly, packaging, and final inspection.

With LOT- or Batch-level traceability, manufacturers can easily identify defects, determine impact range, and comply with standards such as ISO, GMP, HACCP, as well as global requirements in food, pharmaceuticals, and electronics.

This not only reduces recall risks but also strengthens brand credibility.

3. Faster, Smarter Decision-Making

MES provides real-time data through intuitive dashboards. Managers can track KPIs such as shift productivity, scrap rates, inventory status, or material usage.

When integrated with ERP, MES data connects with planning, finance, and HR — giving leadership a holistic view from the shop floor to the boardroom.

4. Cost & Resource Optimization

By automating data entry and reporting, MES significantly reduces supervisory labor costs and eliminates manual errors.

It also helps cut raw material inventory by 10–15% and shorten lead times by 20%, thanks to smart scheduling and real-time responsiveness to market fluctuations.

5. The Hub of Smart Factory Connectivity & the Foundation for IoT – AI – APS

MES acts as the “data orchestrator” among machines, ERP, SCADA, IoT, and advanced planning systems. It is a prerequisite for deploying predictive AI, optimized scheduling, and fully intelligent factory operations.

1. Global Market Momentum

According to The Insight Partners (2024), the global MES market reached USD 16.66 billion and is projected to grow to USD 36.13 billion by 2031, with a CAGR of 11.8%.

The fastest-growing regions include Asia-Pacific – particularly China, South Korea, and Vietnam – where factories are accelerating toward Smart Factory models.

2. Vietnam: From “Trend” to “Action”

Market Research Vietnam reports that Vietnam’s smart manufacturing market is growing at an average of 10.7% annually from 2025 to 2033, driven by strong demand from electronics, F&B, and pharmaceuticals.

Post-pandemic, manufacturers have realized that agility and rapid response are now survival factors. MES – with its real-time data connectivity and line optimization – is becoming a foundational investment.

The Ministry of Industry and Trade is also promoting its “Digital Transformation in Manufacturing to 2030” initiative, where MES is a key priority to enhance domestic production capability.

3. Challenges in MES Implementation

Despite strong potential, many Vietnamese manufacturers remain cautious due to:

- High initial investment, especially for small factories

- Limited IT and operations expertise, leading to reliance on vendors

- Complex integration with legacy systems (accounting, in-house ERP, etc.)

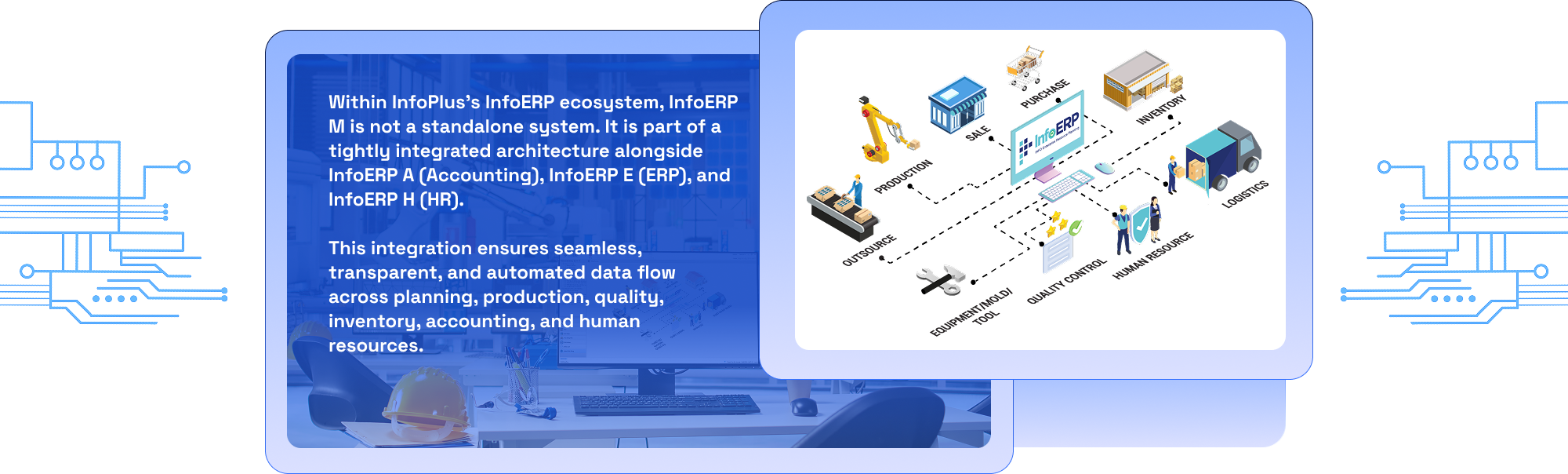

Within InfoPlus’s InfoERP ecosystem, InfoERP M is not a standalone system. It is part of a tightly integrated architecture alongside InfoERP A (Accounting), InfoERP E (ERP), and InfoERP H (HR). This integration ensures seamless, transparent, and automated data flow across planning, production, quality, inventory, accounting, and human resources.

1. Core Capabilities of InfoERP M

- Production Planning & Scheduling: Create, monitor, and adjust plans in real time.

- Work Order & Progress Management: Track work order status, monitor productivity, and capture shop-floor data directly.

- MRP – Material Requirements Planning: Automatically calculates material needs based on production plans, preventing shortages or overstocking.

- Quality Management: Incoming–in-process–final QC, integrated measurement devices, and environmental condition monitoring (temperature, humidity).

- LOT Traceability: Logs production data, material usage, labor, and machine information by LOT for accurate traceability.

- Comprehensive Production Reporting: Fast data export, flexible reporting via Excel or real-time dashboards.

2. Key Differentiators

- Deep Integration with InfoERP A & E: Accounting–inventory–production data is auto-posted, saving time and reducing errors.

- Cloud-Based Architecture: Anytime access with real-time data sharing across departments and management levels.

- Multi-language Support: Optimized for Vietnam–Korea collaboration, ideal for FDI manufacturers.

- User-Friendly Interface: Designed for Vietnamese operational habits, easy to adopt and quick to deploy.

In the digital transformation journey of the manufacturing sector, MES is the missing link between strategy and execution – between ERP and the shop floor.

Manufacturers that adopt MES early will gain a decisive advantage: higher efficiency, lower costs, and faster decision-making.

With InfoERP M, InfoPlus delivers a comprehensive MES tailored to Vietnamese enterprises – integrated, automated, user-friendly, and ready to scale.