In the journey toward digital transformation, there exists a crucial “gap” between the enterprise planning layer (ERP) and the equipment control layer (PLC, SCADA). MES (Manufacturing Execution System) emerged to bridge that gap - serving as the vital link that connects data flow and orchestrates production execution across the shop floor.

According to IBM, MES is “software that monitors and controls manufacturing processes on the shop floor.” In more technical discussions, MES is defined as a software layer that enables execution management, real-time data collection, production tracking, quality control, traceability, and overall equipment effectiveness (OEE) optimization.

Structurally, MES sits between:

According to IBM, MES is “software that monitors and controls manufacturing processes on the shop floor.” In more technical discussions, MES is defined as a software layer that enables execution management, real-time data collection, production tracking, quality control, traceability, and overall equipment effectiveness (OEE) optimization.

Structurally, MES sits between:

- ERP / Enterprise-level Planning and Management Systems (Planning, Finance, Procurement, Sales)

- The Execution and Control Layer (PLC, Robots, IoT Sensors, Automation Systems)

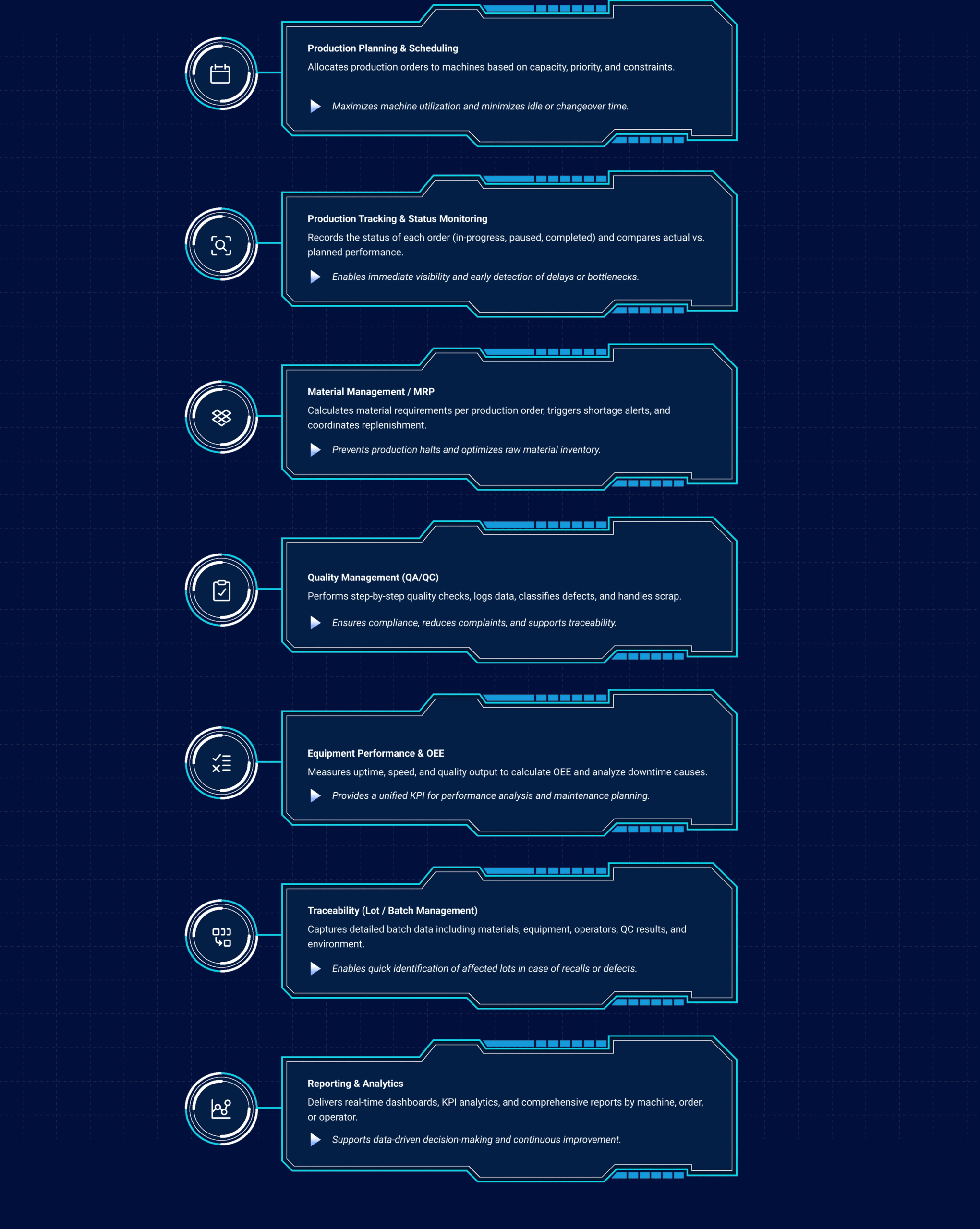

1. Real-time Visibility

In a dynamic manufacturing environment-where material shortages, equipment failures, or order changes occur-having real-time visibility into bottlenecks is critical for agile decision-making. MES provides dashboards, live alerts, and performance indicators that enable instant situational awareness on the shop floor.

2. Optimizing Equipment Efficiency and OEE

MES not only tracks machine status but also measures OEE (Overall Equipment Effectiveness)-a key performance metric that evaluates availability, performance speed, and quality rate. Through MES, manufacturers can analyze downtime causes, implement predictive maintenance, and maximize machine utilization.

3. Quality Management and Traceability

MES enables in-line quality inspection (QA/QC) within production lines. Detailed LOT and batch data are stored systematically, making it easier to trace issues when defects or complaints arise. In regulated industries such as pharmaceuticals, food, and electronics, this level of traceability is not optional-it is a compliance requirement.

4. Synchronization with ERP and Supply Chain

Any changes occurring on the shop floor (e.g., delays or material shortages) must be instantly reflected in ERP systems to adjust planning and coordinate material or workforce allocation. MES acts as the bidirectional data bridge between the factory and enterprise systems.

5. Enabling Flexible and Mass-Customized Production

As customer demand shifts toward personalized products, production lines must adapt rapidly to custom orders. MES supports dynamic scheduling and seamless order switching, maintaining operational continuity while enabling flexible production strategies.

6. Reducing Operational Costs and Waste

By tracking detailed production data-raw material consumption, defect rates, idle time, and changeover losses-MES helps identify inefficiencies and eliminate waste across the entire manufacturing value chain, leading to leaner and more cost-efficient operations.

In a dynamic manufacturing environment-where material shortages, equipment failures, or order changes occur-having real-time visibility into bottlenecks is critical for agile decision-making. MES provides dashboards, live alerts, and performance indicators that enable instant situational awareness on the shop floor.

2. Optimizing Equipment Efficiency and OEE

MES not only tracks machine status but also measures OEE (Overall Equipment Effectiveness)-a key performance metric that evaluates availability, performance speed, and quality rate. Through MES, manufacturers can analyze downtime causes, implement predictive maintenance, and maximize machine utilization.

3. Quality Management and Traceability

MES enables in-line quality inspection (QA/QC) within production lines. Detailed LOT and batch data are stored systematically, making it easier to trace issues when defects or complaints arise. In regulated industries such as pharmaceuticals, food, and electronics, this level of traceability is not optional-it is a compliance requirement.

4. Synchronization with ERP and Supply Chain

Any changes occurring on the shop floor (e.g., delays or material shortages) must be instantly reflected in ERP systems to adjust planning and coordinate material or workforce allocation. MES acts as the bidirectional data bridge between the factory and enterprise systems.

5. Enabling Flexible and Mass-Customized Production

As customer demand shifts toward personalized products, production lines must adapt rapidly to custom orders. MES supports dynamic scheduling and seamless order switching, maintaining operational continuity while enabling flexible production strategies.

6. Reducing Operational Costs and Waste

By tracking detailed production data-raw material consumption, defect rates, idle time, and changeover losses-MES helps identify inefficiencies and eliminate waste across the entire manufacturing value chain, leading to leaner and more cost-efficient operations.

- According to Transparency Market Research, the global MES market was valued at approximately US$16.9 billion in 2024, projected to reach US$51.2 billion by 2035, growing at a CAGR of ~10.6%.

- The Insight Partners reported a 2024 market size of US$16.66 billion, forecasted to reach US$36.13 billion by 2031 (CAGR ~11.8%).

- Future Market Insights estimated the 2025 MES market at US$23.24 billion

- GMI Insights valued the 2024 market at US$15 billion, expecting it to grow to US$39 billion by 2034 (CAGR ~10.2%).

Across research institutions, MES consistently appears as a high-growth segment, driven by the accelerating demand for smart factory digitization worldwide.

In Vietnam, the smart manufacturing trend is also gaining significant traction:

- Market Research Vietnam projects a CAGR of ~10.7% (2025-2033) for the country’s smart manufacturing market.

- Ken Research estimates that in 2023, the Vietnamese smart manufacturing market-including equipment and software solutions-reached approximately US$105 billion.

MES is not merely a production management tool-it is the central orchestration hub of the smart factory, connecting people, machines, and data in real time.

In the era of Industry 4.0, where speed and precision define competitiveness, MES empowers enterprises to see, understand, and optimize every aspect of manufacturing operations.

In the era of Industry 4.0, where speed and precision define competitiveness, MES empowers enterprises to see, understand, and optimize every aspect of manufacturing operations.

InfoPlus's Customer Service Department is always ready to respond and support to customers' inquiries about software services & solutions